After my previous blog, Phil Cooper of Xodus wrote, ‘No need to worry about experience leaving the industry. Automated design, IoT and Machine Learning will take care of everything!’ Now I am not sure if he was kidding or not, but that comment made me ponder ‘could the offshore industry in general, and the subsea sector more specifically, operate with fewer engineers and depend on computers and robots to answer all the questions and solve all the problems?’

So I set my brain to whirring – just like some robot – on the question of whether automata could solve the many and varied challenges that confront engineers during the course of a project or the life of a field. I thought back about things that I had witnessed over my 30 plus years of reporting on the offshore and subsea sectors.

At the back at the end of the 1980’s, I spent some time with Seanor, a small-ish Norwegian engineering company. It was involved in a design project for a subsea manifold and on the Friday I was in its office, the team discovered a pipe clash in the drawings. The team now had to reproduce all of the structural documentation minus the clash and as it had one of the first – and maybe the first? – computer-aided design (CAD) programs on a computer linked to a printer, it set the machine to run over the weekend in order to have the new drawings available on Monday morning.

There are several points to ponder here. Firstly, CAD – everyone has CAD systems now, but back then it was special. Secondly, it was early on in the advent of computer power, so it was still going to take some time to re-print the drawings, although faster than a draughtsman with a slide rule and a pencil. Thirdly, this was well before the internet was commonplace and being ‘online’ had almost no meaning at all, so there was no worry about someone hacking the system while it was running for three days. While this was quite a long time ago and at an early juncture in the use of computers, it proved their value for such a task – reproducing a document based on a repetitive task.

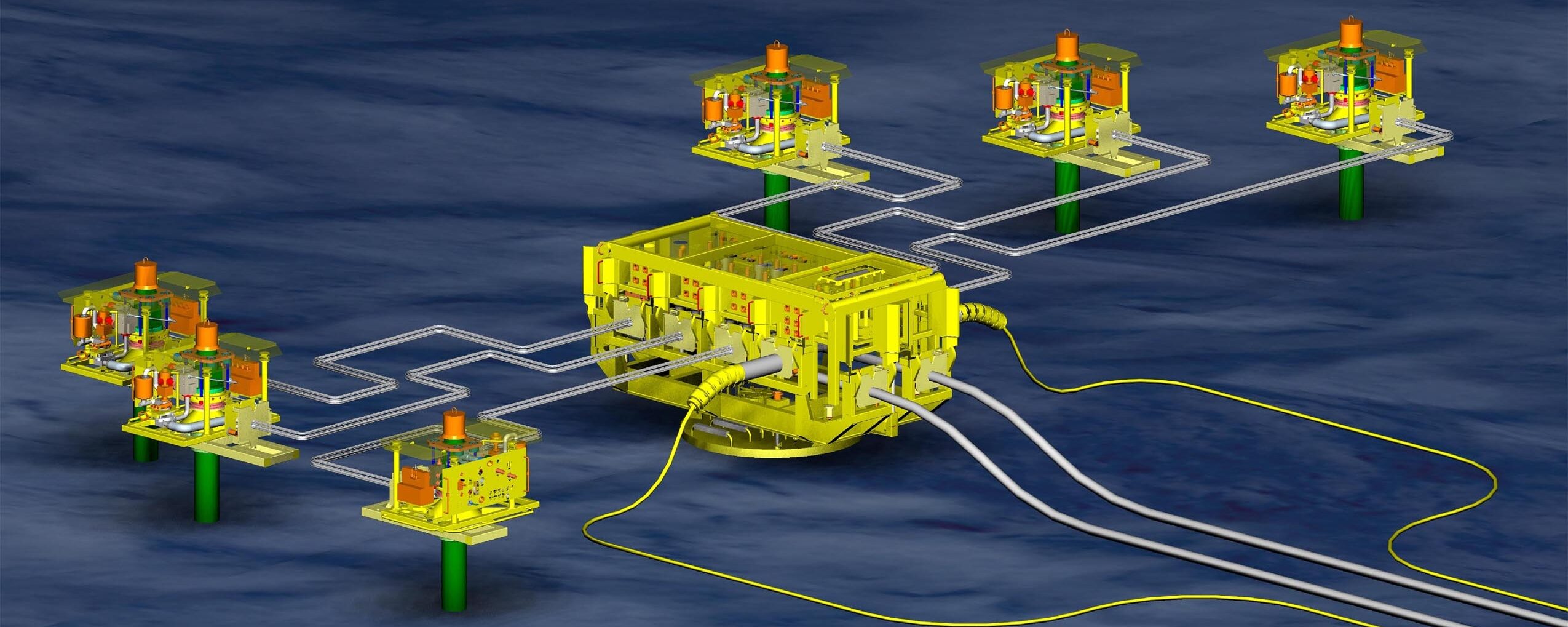

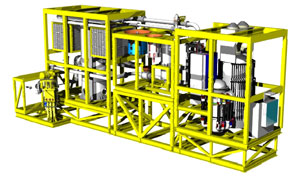

Scroll forward four or few years to the installation phase of two of Norway’s landmark subsea projects – Norsk Hydro’s TOGI (Troll Oseberg Gas Injection) and Saga’s Snorre subsea production station. Both projects – at the time Norway’s deepest multi-well systems based on template-manifolds – experienced significant problems prior to first production, although it might be said to be generous to describe the issues so kindly.

At TOGI, during the diverless pipeline pull-in which at the time was one of the biggest (20in) ever carried out at such water depths (303m), seabed debris fouled the surface of one of the end facings, preventing proper sealing and completion of the clamping. Kvaerner had to come up with a scheme to clean the pipe end face. I can not remember exactly how long it took, but it came up with a solution, completed the pull-in operation and the field came onstream. At Snorre SPS, there was an inherent fault with the control system cabling which all had to be replaced before the field could come into production.

I don’t believe that either of these problems could have been sorted out by a robot. The first was a problem solving issue matched with an operational scenario involving remotely operated tooling. The second was simpler – a retrieval and re-installation operation – but required painstaking work and many dives by an rov. How could AI have expedited this?

There are many examples of such scenarios which require the lateral thinking commonly associated with human beings and currently beyond the grasp of a robot. So yes, robots and AI could assist humans and fill the gaps for some tasks that humans can do, but could be bored by. Maybe robots could do some platform maintenance tasks that do not require ingenuity. The more complex, problem solving will remain, for the time being, the purview of humans, along with the types of physical jobs that might be beyond the capability and flexibility of robots. Just think about those early Dr Who episodes where the Daleks were stumped by a flight of stairs.

***************************************************************************************

My Google search, like those of many others, is set to pick up any internet references to offshore, subsea, pipelines and floating production systems. It seems, though, that the majority of the items that appear nowadays are about a variety of marketing reports on subsea production, subsea controls, subsea grids, subsea anything, along with similar reports on future pipelay installations and concrete weight coatings and future floater projects. People have been making money from market reports for quite a long time, but these days, there seem to be more market reports than there are projects. And who are these people producing these reports anyway?

***************************************************************************************

I spoke at two Subsea UK events at the end of last year about the history and future of technology. What struck me was that a number of young engineers came up to me to say that they did not know the the origin of the technology that they were specifying. Maybe someone with a long perspective on the subsea business needs to run a subsea history course. Hmm.

***************************************************************************************

As I am new to his blogging business, I failed to have a visit counter installed for the first one, but managed to get it up and running not long after posting No 2. Even I am impressed – 310 visits after just three days – so time for potential supporters, ie advertisers, to pile in. Hint, hint.

8 thoughts on “Can AI cut the cost of subsea engineering?”

Thanks Steve. You succinctly demonstrate how the great new AI and other computer-based technologies are a tremendous help in analysing and facilitating solutions to problems and challenges. They don’t replace the human experience, but they can very much amplify it’s effectiveness (in the right hands 🙂

Incidentally, my rather rusty recollection of the TOGI skimming tool connector repair in those late 80’s is that it took about 4 months from first diagnosis of the damaged seal face, to getting a successful test of the repaired seal. That was a truly brilliant recovery by the team – very much enhanced by the ingenuity of Hydro’s diving specialists, despite being one of the first big subsea problems encountered beyond diving depths.

Yes I like to be in touch and read all the pros and cons , but after 3 years working in Houston on the biggest blow out , would find it difficult to tell the court it is because of “automated design” this as happened , to devastated people. How do you interrogate or make the computer design responsible ? Ain’t you a responsible eng. ? Unfortunately my old friend Red Adair is not there anymore , but think about the old guy when working in my garage with zero safety in mind.

The basic system works with me , design by, reviewed by , approved by !

Whilst working on Agip Toni for Cameron, we had some offshore tigers supporting us that came off the TOGI project (TOGI to Toni?) and they, as a large number of folks do in the industry, wouldn’t stop talking about their last project! For the rest of us they became the TOGI bears, which still makes me chuckle today!

Nice story. Thanks for reading and commenting. Wo#ho do u work for now?

Nice one Jason – it’s taken me a long time to realise that I too am a Togi bear! It was a great team to be a part of, for sure. The nearest I’ve come since then to a similar can-do team spirit, fully supported by slick management responses, was the Reliance Industries romantically named KG-D6 challenge in the Bay of Bengal.

Steve,

History, robots, computers, any new technology, new R&D groups, etc. etc.. The kind of questions that you used to get – a list of things that you were supposed to put in order of importance. If you answered “all of the above” the old bugger (like me) up front gave you 0/10 even though it was the right answer. First point, the real problem is the old bugger up front. By and large the industry is still doing what he did 40 – 60 years ago – same mistakes, and cowardly approach to personal or technical risk. Too many still believe in the million monkey business. That is where the history, robots, etc, business comes in. There are a lot of clues in history b ut they are not easy to uncover and utilize. Sorting through all the junk and identifying the critical element of modern technology, wheter it me nano technology, or whatever is far from easy but, and it’s a big but, other disciplines are doing things even more difficult. A short time ago I had a discussion with a young relative, an MD, who id modeling part of the brain to better understand autism. He has access to a mountain of non-linear neuron response data. He can invert a 100×100 matrix in seconds. I spend 9 months using NASA’s Apollo backup computers to invert a measly

12×12 matrix. That’s the second point, computational capability combined with youthful ideas can do magic. For the past few years I have assigned a cost reduction coursework assignment for my students – it is very encouraging the way that the better ones marry olds ideas with new capabilities to yield cost and schedule reduction – the fresh look old ideas combination can, in a positive environment yield more than 20% improvements.

A final note on the risk taking business. Enjoyed seeing input from Iam Ball. Whenever we meet, we (secretly of course) regale ourselves with remembrances of a subsea well we worked on – worst well in history! Funny after 40 years but the important thing is that we both survived without having to resort to something less exciting, denistry, accounting, journalism,etc. to survive.

Best regards,

Bil

Maybe if all the collective experience and field data (good and bad) was more widely accessible an AI could be gainfully employed in organising that data, looking at trends and patterns, and maybe flagging up potential issues before they become reality. That would help in each of the design/review/approve process stages (but not replace them!). But maybe I missed the bit where everyone started to openly shared failures as much as they shared successes…

Thanks Tony : Words like failure are not used in banking, hence if you cannot get your money out and may sometimes later get it ? The Gov step in and call it a bail out…and everyone keeps quiet. I would agree with your comments that we should not re invent the wheel , what lesson is learnt ? if the cause(s)and follow up is carefully missed out of the eng. media, don’t talk about it ! Being an operator does not require to have the highest % financial exposure ?the others have to keep their commitments, when things go wrong .What surprises me is where operators get their collateral bail out money ? Considering the risks and what an offshore failure turn out to be, one guy in the Shetlands told me don’t worry same as the banks.